English

English 简体中文

简体中文  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Galego

Galego  繁体中文

繁体中文  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

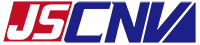

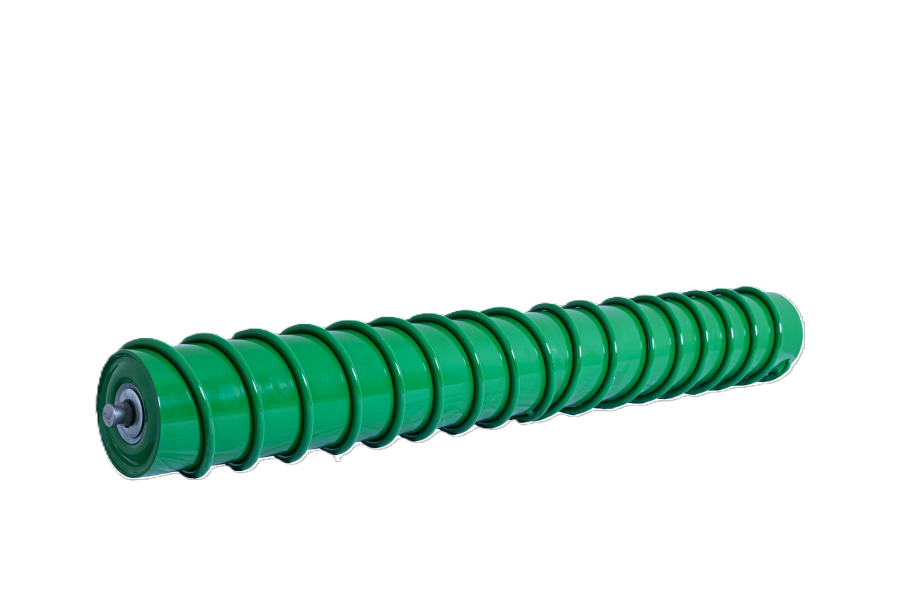

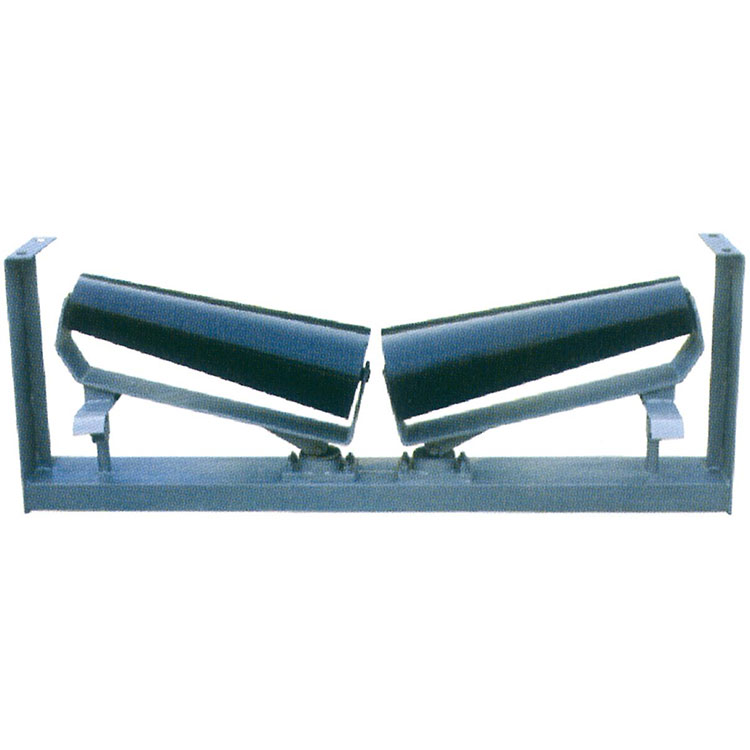

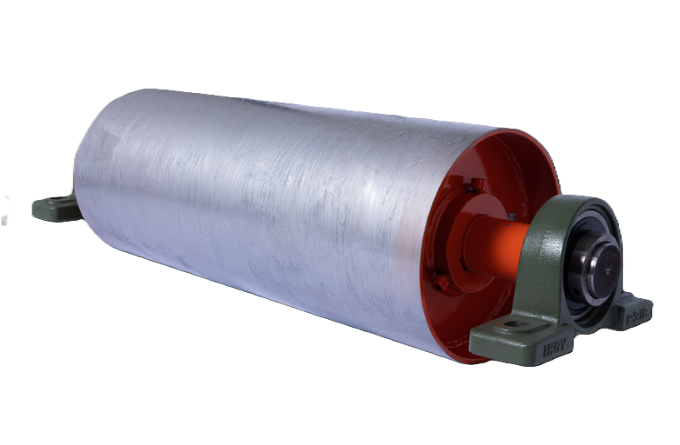

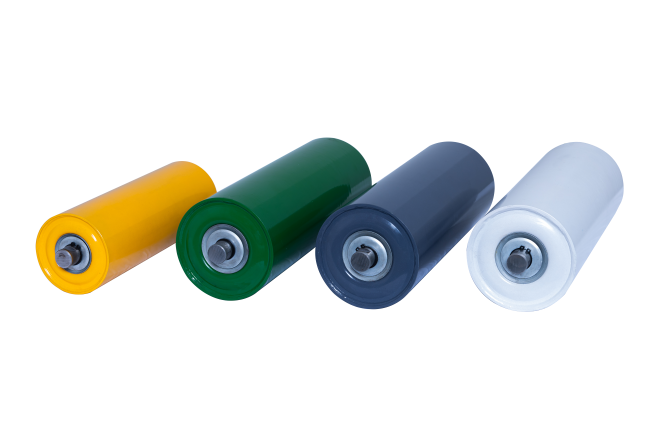

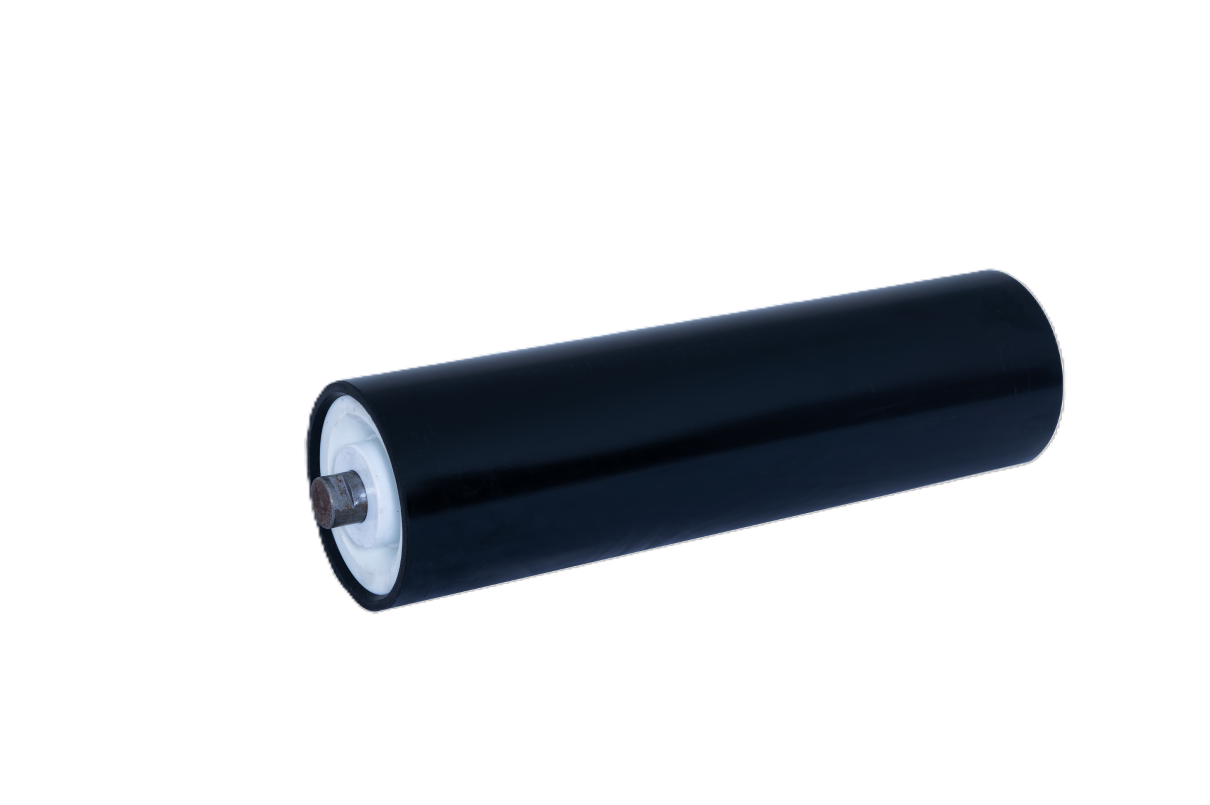

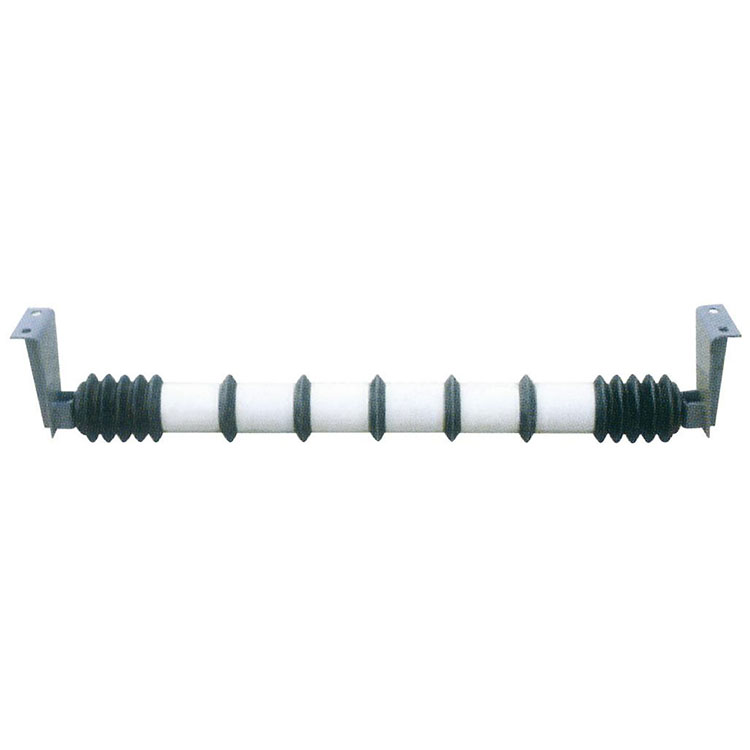

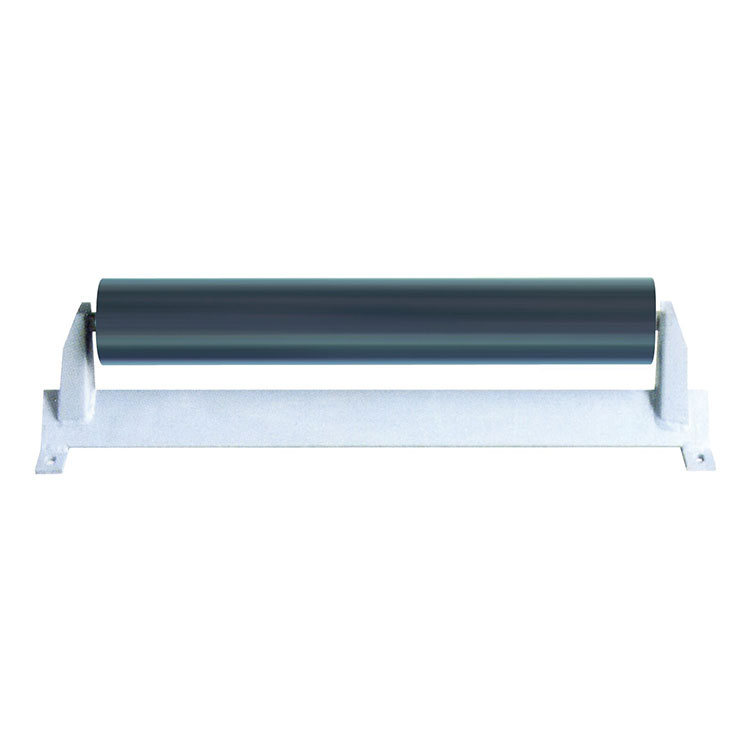

Ukuthwala i-roller

Thumela Uphenyo

Inzuzo yokuthwala i-idler:

No.1. Ukunemba okuphezulu kanye ne-welvency ye-weldency ye-weldency yamukelwa ngesembozo se-roller, nge-radiout encane ye-radial kanye nebhalansi enhle.

Cha .2 Amafreyimu wethu we-Intler akhiqizwa engxenyeni enokulungiswa okunembile. Imishini ye-CNC nokubeka indawo ephezulu.

Cha.

No.4 Ukuthwala I-Idler Ukukhetha izinsimbi zekhwalithi yekhwalithi, ukuguquka kwe-CNC nokugaya kwamukelwa ukuqinisekisa ukunemba.

Cha.5 Isikhombisi se-Idler ye-Coneveror senzelwe ngokukhethekile ukumelana nokuphikiswa okuphansi kokunxephezelwa okuzenzakalelayo, ukunxenxa okuzenzakalelayo kanye nokungenzi manzi, ukuqinisekisa ukuthambisa isikhathi eside okumnandi.

|

Ububanzi beBelt

B

|

L | L1 | L2 | D | d | b | Uhlobo lokuthwala |

| 500 | 190 | 200 | 220 | Φ89 | Φ Uma0 | 14 | I-4G204 |

| 600 | 610 | 640 | |||||

| 650 | 240 | 250 | 270 | ||||

| 750 | 760 | 790 | |||||

| 800 | 305 | 315 | 335 | ||||

| 950 | 960 | 990 | |||||

| 1000 | 375 | 385 | 408 | Φ 1080 | Φ255 | 18 | 4g305 |

| 1150 | 1160 | 1200 | |||||

| 1200 | 455 | 465 | 488 | ||||

| 1400 | 1410 | 1450 | |||||

| 1400 | 525 | 535 | 558 | ||||

| 1600 | 1610 | 1650 |